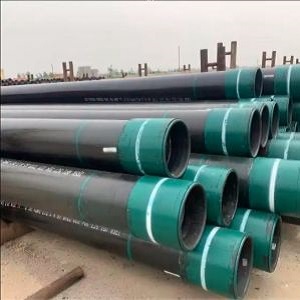

Oil Country Tubular Goods (OCTG) casing plays a vital role in the exploration and production of oil and gas wells, providing structural support and facilitating the extraction of hydrocarbons from the subsurface reservoirs. OCTG casing sizes vary widely to accommodate different well conditions, including depth, pressure, and formation characteristics. In this comprehensive discussion, we'll explore the various OCTG casing sizes commonly used in the oil and gas industry, their dimensions, classifications, and applications.

1. Classification of OCTG Casing Sizes

OCTG casing sizes are classified based on their nominal outside diameter (OD) and wall thickness. The American Petroleum Institute (API) sets standards for casing sizes and specifications, which are widely adopted in the industry. The most common classifications of OCTG casing sizes include:

Nominal Outside Diameter (OD)

Casing sizes are typically designated in inches, ranging from 4 1/2 inches to 20 inches or more. Larger casing sizes are used for deeper wells and higher-pressure environments.

Wall Thickness

Casing wall thickness is specified in terms of "weight per foot" or "thickness designation." Thicker walls provide increased strength and resistance to pressure, but they also result in heavier casing strings and higher costs.

2. Common OCTG Casing Sizes

4 1/2" Casing: This is one of the smallest casing sizes used in oil and gas wells. It is commonly used in shallow wells, injection wells, and surface casing strings.

5 1/2" Casing: 5 1/2-inch casing is widely used in both exploration and production wells. It provides structural support and helps isolate different formations to prevent fluid migration.

7" Casing: 7-inch casing is often used in intermediate sections of wells, where higher pressures and temperatures are encountered. It provides additional strength and integrity to the wellbore.

9 5/8" Casing: This casing size is commonly used in production wells to accommodate larger production tubing and provide support for the wellbore.

13 3/8" Casing: 13 3/8-inch casing is typically used as surface casing or conductor casing to support the uppermost part of the wellbore and isolate shallow formations.

16" Casing: Larger casing sizes, such as 16 inches, are used in special applications or wells with significant production requirements. They provide ample space for production tubing and downhole equipment.

3. Selection Criteria for OCTG Casing Sizes

The selection of OCTG casing sizes is influenced by several factors, including:

(1)Well Depth

Deeper wells require larger casing sizes to withstand higher pressures and provide sufficient structural support.

(2)Formation Characteristics

The characteristics of the subsurface formations, including lithology, pressure, and fluid properties, influence the selection of casing sizes and specifications.

(3)Pressure and Temperature Conditions

Higher-pressure and higher-temperature environments require stronger and thicker casing strings to maintain integrity and ensure safety.

(4)Production Requirements

The anticipated production rates and fluid volumes dictate the size and design of the production casing string.

4. Specialized OCTG Casing Sizes

In addition to standard casing sizes, there are specialized OCTG products designed for specific applications, such as:

(1)Premium Connections

High-performance threaded connections with enhanced sealing and mechanical properties for demanding well conditions.

(2)Expandable Casing

Casing strings that can be expanded downhole to improve wellbore stability and enhance production.

(3)Corrosion-resistant Alloys

Casing materials with enhanced corrosion resistance for sour gas environments or offshore applications.

Article source: https://article-realm.com/article/Business/58519-Octg-casing-sizes.html

Reviews

Comments

Most Recent Articles

- Nov 5, 2024 Affordable, World-Class MBBS in Uzbekistan with Ria Overseas’ Expert Guidance by Mbbsinblog

- Nov 5, 2024 Acute and Chronic Allergic Conjunctivitis Treatment Market Size Analysis 2031 by faraz pathan

- Nov 5, 2024 Affordable, Quality Medical Education with Global Recognition for Indian Students by Mbbsinblog

- Nov 5, 2024 Remote Electrical Tilt Device Market Revenue, Industry Growing Demand Up To 2031 by faraz pathan

- Nov 4, 2024 Directory of Waste Management Companies - Waste Management Directory by EcoHubMap

Most Viewed Articles

- 4095 hits Flexographic Printing Plates Market Size, Share, Report 2024-32 by ellyse perry

- 2719 hits Mist Sprayer Pumps Market Demands, Trends, Industry Analysis, Segmentation by 2032 by ellamrfr

- 1309 hits Plastic Bottles and Containers Market to Signify Strong Growth by 2024-2031 by mansi jain

- 818 hits Thin Wall Packaging Market to Witness Growth Acceleration by 2029 by faraz pathan

- 759 hits Air Traffic Control Equipment Market to Witness Robust Expansion by 2029 by faraz pathan

Popular Articles

In today’s competitive world, one must be knowledgeable about the latest online business that works effectively through seo services....

77514 Views

Are you caught in between seo companies introduced by a friend, researched by you, or advertised by a particular site? If that is the...

33029 Views

Walmart is being sued by a customer alleging racial discrimination. The customer who has filed a lawsuit against the retailer claims that it...

14056 Views

If you have an idea for a new product, you can start by performing a patent search. This will help you decide whether your idea could become the...

11257 Views

Statistics

| Members | |

|---|---|

| Members: | 15673 |

| Publishing | |

|---|---|

| Articles: | 64,357 |

| Categories: | 202 |

| Online | |

|---|---|

| Active Users: | 271 |

| Members: | 4 |

| Guests: | 267 |

| Bots: | 17531 |

| Visits last 24h (live): | 1640 |

| Visits last 24h (bots): | 36522 |